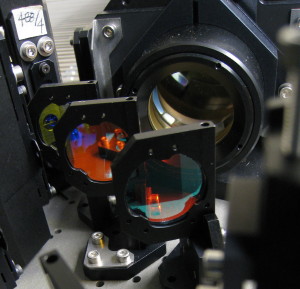

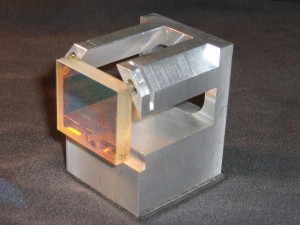

This instrument entered production in November 2008 in California. It uses repeating architecture to reduce the total number of unique parts by 40%. The lens seen in the photo has an NA of one. There are several major assemblies including a laser with cooling system, steering filters, five photomultipliers, and other components. (Client confidential.)

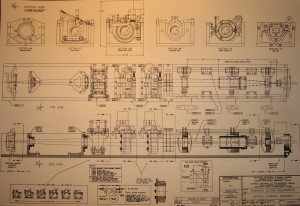

An example of structural design. Components were designed to mount new radio dishes in the seven-telescope linear array. (Dominion Radio Astrophysical Observatroy, Penticton BC)

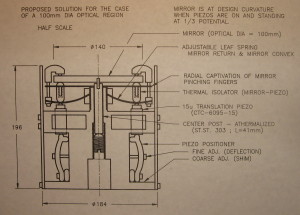

Part of an analytical study, this design uses six piezo actuators and one fixed point. Operating frequency ~100 Hz. (Herztberg Institute for Astrophysics, NRC)

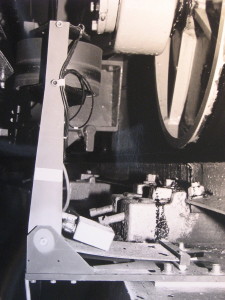

As part of the upgrade to an observatory, the rotational position of the dome was encoded. Four quadrants provide indexing address points. Between these points, the wheel shown (the small, vulcanized black wheel, upper left, not the pulley) counts pulses. Two LED/sensor pairs, 90 degrees out of phase give rotational direction. (Dominion Astrophysical Observatory, Victoria, BC)

This instrument is used for such things as the mapping of star surfaces. It was designed to be adaptable to virtually any telescope facility. It is one of the few designs I've completed (like the cytometer) where all fabrication, assembly, and testing occured thousands of miles away. I have never seen this instrument! But it has produced science at more than one facility. (Contract commissioned by UWO and Brandon U)

Made to demonstrate that optics can be mounted in a strain-decoupled manner without compromise to the mount's requirement to operate in a vibration environment. This mount leaves the mirror flat to one-tenth of a wave across a temperature range of +/- 30C, yet the vibrational modes that are capable of causing steering errors occurs at such high frequencies that their corresponding amplitudes are too small to detect. (for Creo Products, Vancouver)

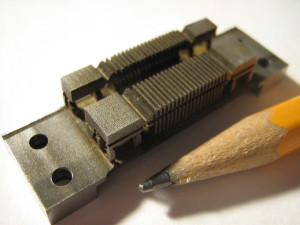

Electro-dsicharge machining makes it possible to fabricate this small, complex device as a single part. Within the component are micro-flexures that enable sub-millimetre optics to be positioned along one axis, while other flexure-based heads (at either end of the array) are used to clamp the optical alignment blades in their final positions. (Client confidential)